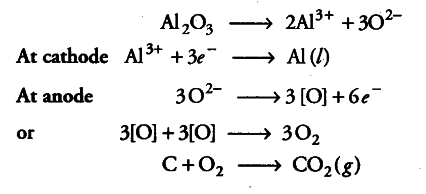

Materials used for making anode especially with graphite. There will be a lot of ranges and well classified in this article. graphite powder for li-ion battery anode has many setting used in manufacturing. The same procedure is followed by commercial to laboratories for production. There are different portfolios used for comparing the performance of anodes. Mainly anodes made with graphite usually have great performance. These anodes could be optimized to use. In multiple varieties of industrial applications. Optimization includes different formats either small or large. This should satisfy the needs of a consumer in electronics. The formats of large mostly used lithium-ion based. These are preferable mostly in the present market. Apart from these products which are existing in the market. People used for developing anodes of graphite either custom or commercial usage. So many materials are used for making of these batteries by the manufacturers. Sometimes these graphite batteries are made according to the requirements of specific.

The materials of tar-grey best suited for graphite anodes. These materials can be satisfied by manufacturers of batteries of lithium-ion. The popularity of these anodes is excellent in the ratio of lengthier life cycle and cost-performance. A reader can go through this article for complete information.

Why the adoption of graphite anodes:

In this modernized world for everything, there will be a reason to follow. Likewise, still the users are habituated to fossil fuel. In the future, the usage of these fossils may halt suddenly. In order to survive in such a situation in the future the following are helpful. With the help of advanced technology batteries of lithium based. With the option of capacity reversing usually more than required can be possible. Process of reversing can be done approximately forty charging per discharging-cycles. Anodes are extracted from based of silicon. This technology would doubles capacity of anode which is conventional to graphite. Almost similar technology can be used in making these reserving batteries. The main motto of making these batteries are capacity and higher density are maintained. Scientists have came the conclusion about the fossil. People have use powdered fuel of fossil to move their motor vehicles. These will be common sources around the world irrespective of the development of their nation. People just need to plug-in their vehicles electric socket with power. This automatically presents the significance in both environments and economic benefits. At the same moment it is a challenge for developing next generations technology of making battery. Developed alternative should be ready to offer greatest density. The ultimate solution for best remedy are silicon based li-ion batteries. Vehicles of electrical which rely-on batteries of nickel-metal. But these batteries are bulky, heavy and lower energy rates. These are not suitable for long drives. Commonly used in handling electronics with great experience. These batteries constitute mainly of Anaheim made of graphite, electrolyte and a cathode.

The electrolyte adopted should be solvent of organic. Apart from advantages there will be some limitations too. Lithium should be added continuously to the graphite while on use. Sometimes removing the battery also needs battery operation. This process is similar in all batteries based on graphite. The above mentioned are main reason for adopting graphite in making batteries. Hope readers would find really an interesting facts about batteries.